Automation software platform for Automotive Manufacturing

Leave your details and we will contact you

In the automotive industry, where price wars and competitive pressure reign, the zenon software platform is a flexible support tool to help you achieve your operational goals. Heterogeneous hardware scenarios can be integrated easily and quite simply. Even equipment that is later incorporated into a production process can be incorporated without major problems.

zenon is extremely flexible and open, providing horizontal and vertical integration from one end of the process to the other, from a single sensor to an entire organization. The data obtained from different plants can even be compared by the cloud. The solution based on the zenon platform is taking automotive manufacturing to the next level, with several global cases.

Challenges Facing Car Manufacturers

The automotive industry experiences a variety of challenges in its production. The main setbacks below make it difficult to achieve good productivity indicators:

- Production shutdowns: The automotive manufacturing industry is often forced to halt production at various sites due to a lack of skilled labor or imposed health and safety conditions. These production stoppages made it difficult to meet production targets required to maintain production levels and, consequently, revenues.

- Reduction in vehicle sales: As a consequence of production stoppages, the reduction in sales impacts the profitability of the operation

- Disrupted supply chain: Supply chain disruptions negatively impact the industry. Without sufficient inventory of necessary parts, vehicle production suffers from reduced or even interruptions.

- Shift to e-mobility: As demand shifts to more embedded technology, manufacturers need to shift production facilities or equipment to keep up with these demands.

How zenon helps car manufacturers

COPA-DATA’s zenon software platform is a world-class solution for automotive manufacturers. zenon can help you in all areas of automotive manufacturing, from the supply of parts to the delivery of the finished vehicle. These industry challenges can be significantly reduced or solved. zenon helps automotive manufacturers in several ways, including:

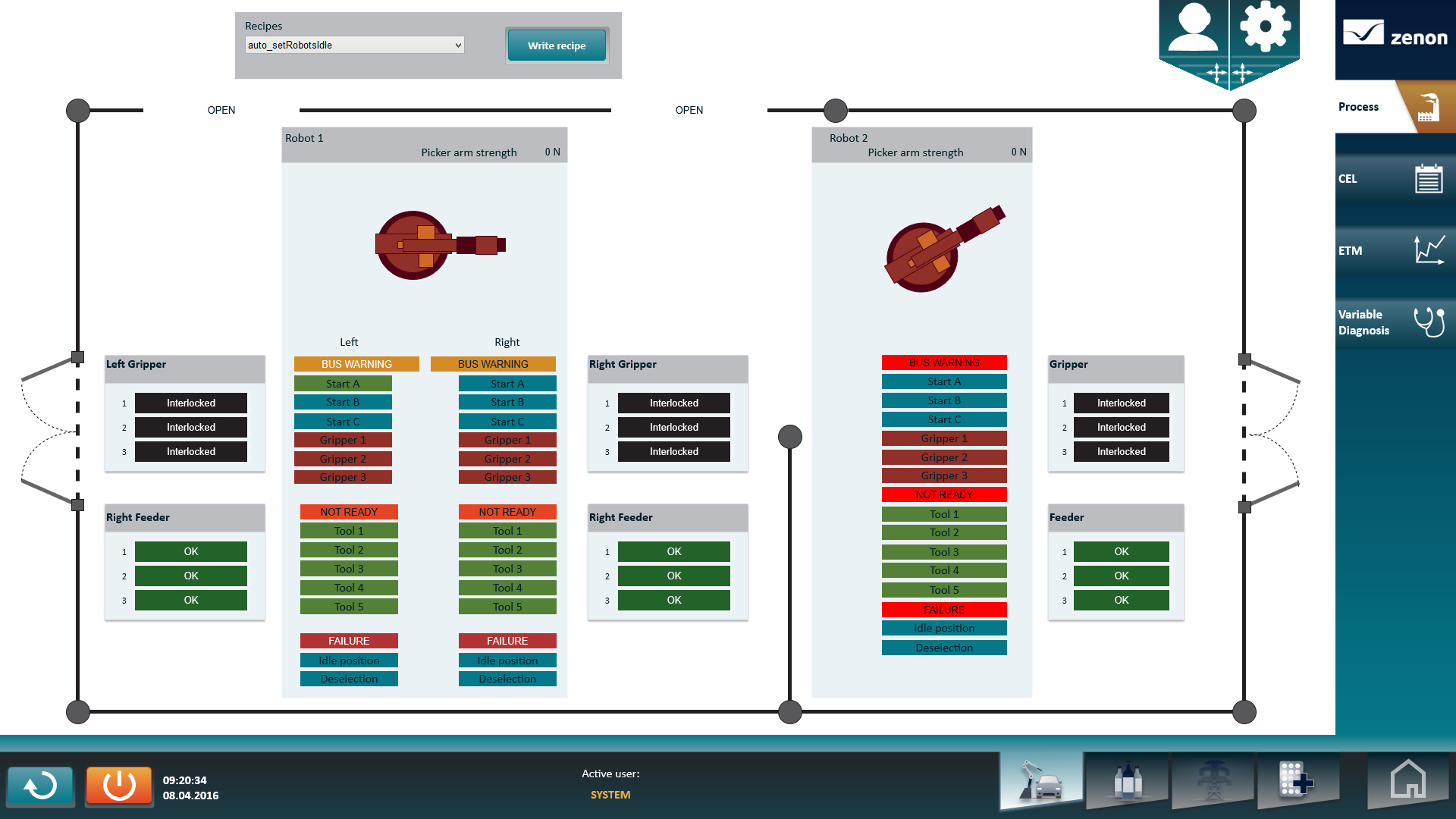

Visualization and control: Automotive companies utilize visualization software to create graphs of equipment and other plant conditions. With zenon, you can monitor complex manufacturing systems and data with ease. In turn, their production processes become easier to understand and their interfaces are more user-friendly. Easy-to-use interfaces and rapid development make systems more accessible to stakeholders, from design to production and management.

Analytics: As automotive companies struggle with production rates and consumption trends, staying up to date with data analytics is crucial. With proper data analysis techniques, zenon helps you analyze consumer trends and adapt to upcoming projects. zenon provides comparison data for your entire plant and competitors. zenon’s customized reports on production trends help you optimize your efficiency — comprehensive data allows you to maximize automotive production.

Data acquisition: At zenon, when we talk about data acquisition, we are referring to the change from working only with “guesswork” tips to working with traceable digital data. Automotive manufacturers use constantly acquired data to identify trends. zenon Data Services classifies and archives data from all the company’s operations. With all your data in one centralized location, you can get analytics and quickly turn it into action.

The benefits of zenon for automotive manufacturing

In addition to the specific challenges of the automotive segment, the zenon platform also has functionalities and characteristics for your day-to-day as a developer, maintainer, or operator, far superior to its competitors:

Preparing for eco-friendly initiatives: Reducing CO2 emissions has become a goal in all manufacturing industries. Despite the challenges that constrain a fully green operation, zenon prepares automotive companies for green initiatives. The platform focuses on reducing energy consumption. Using the historic, ready-made, and tested records, functions, and specific objects, you can track energy consumption across your business and identify ways to improve energy efficiency. By reducing your energy usage, you can become a greener business overall. And still use this data, analysis and report issued for certification, as they all comply with the ISO 50001 standard.

Simple integration: With zenon, integration into your company’s current systems is simple and fast, thanks to its more than 300 communication drivers for PLCs, devices, field networks, even legacy ones. You can introduce a device or system and immediately start collecting and analyzing its data.

Reduced likelihood of errors: When entering data manually, you run the risk of human error or miscalculations. Our software collects production data in real-time and seamlessly integrates it with the rest of your production landscape. Reduces the ability to error, making your data more accurate.

Quick reaction to alarms: Alarms are crucial in factories, alerting workers when something is wrong. The zenon software platform integrates, compares and manages alarms, enabling faster alerts and action.

Personalized user experience: With the globalization of automobile production, it is not uncommon for production lines to be moved from one plant to another, in accordance with the company’s global strategy. zenon’s power to adapt to the preferences and needs of either the operator or the maintainer makes it possible to change the color palette, brightness or layout of the user interface to create your personalized experience. Have you ever thought about the inclusion of a visually impaired employee operating a production line? In addition, of course, to the interface language, which can be changed with just a click of the mouse.

Some of our clients