zenon Automation Platform applied to the process industry

Leave your details and we will contact you

zenon applied to the process industry

Whatever the sector of the process industry, or how heterogeneous its subsystems are, zenon will help you achieve your operational goals. Our mission is to make digital work as easy as a child’s toy, both for the management of organizations and for their employees. zenon industrial automation software was born from the philosophies “Do it your way” and “to make your life easier” and are applied equally from engineering/maintenance to the operation itself. The zenon platform is characterized by its ease of use, flexibility, and scalability. Industrial automation with the zenon software platform allows you to identify optimization opportunities and make the most of the potential, not only of your process, but also of the entire organization.

Advantages for users

zenon can be integrated with virtually no effort into existing environments, whether for controlling, visualizing, data evaluation, or even as an end-to-end automation software solution. Thanks to its high scalability and the ease with which new machines, equipment and systems can be integrated, zenon also offers potential for scale-up production facilities. The features of the zenon software platform provide efficient engineering, data security and a consistent focus on usability. As a user, you benefit from customized automation of your processes to meet your specific needs.

A wide range of possible applications

The wide and varied range of possible applications for the zenon platform reflects the versatility of the software platform itself. Whether your mission involves managing your plant’s energy data in accordance with ISO 50001, whether you are optimizing your operational data with analysis and reporting, or whether you intend to implement HMI and SCADA projects, the zenon software platform will help you achieve your goals. zenon can also be deployed to monitor buildings and infrastructure, manage the flow of cargo within your organization, or monitor ancillary equipment.

The zenon effect

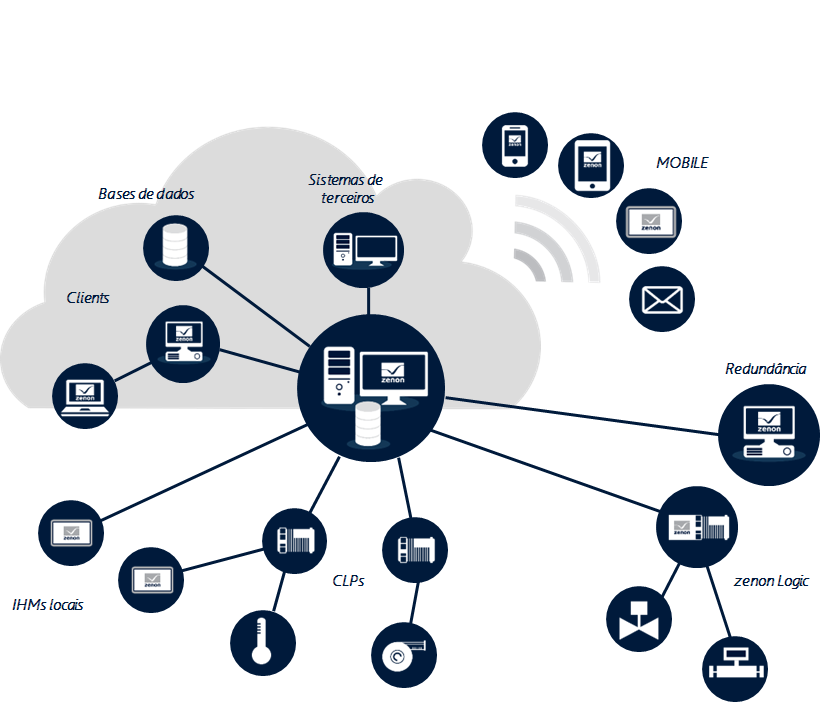

Using zenon, you can answer everyone to the various requirements of all your users. The needs of system integrators, for example, are easily reconciled with the desires of end customers. The zenon platform meets all the requirements of your project: from the design and development of a control room with multiple monitors, to an entire installation being monitored by a laptop that connects to various network points, through protocol gateways, integration from the programmable controller to the ERP or the cloud, even a multi-level SCADA system of automation, all with the same zenon runtime.

zenon also supports a variety of different tasks in its operation. The operator is interested in data and information that is different from the data that interests the management team or the maintenance technician. Ideally, everyone should have a vision tailored to their individual needs, and zenon allows you to design your automation according to a wide range of requirements. These possibilities include filtered views, automatic adaptation to monitor resolutions, simple reuse of designs, and smart Chameleon® technology.

Integration as a competitive strategy

Manufacturing processes are complex, and facilities always have a wide variety of equipment and systems. The production process itself is complex, but so must ancillary equipment and building systems. Integrating these systems can make it easier to control the production process and environment and ensure that it is optimized to increase productivity. The features that zenon offers allow you to keep track of your entire production system and see how the different parts interact. This improved visibility can help you find ways to improve efficiency and productivity.

The 300+ native drivers and industrial protocols that zenon offers help make integration easier, even if you have many different types of equipment from different manufacturers and generations. zenon Historian, for example, can use native drivers to connect to any system, be it an ERP, MES, or any other system, without changing third-party applications.

You can also integrate all levels into a single monitoring system with zenon, including chronological event lists, alarms, test logs, archiving, and more, all on a single platform. This provides improved data analysis and presentation, which helps you gain better insights into your systems and how to improve them.

What’s the point of efficiency without security?

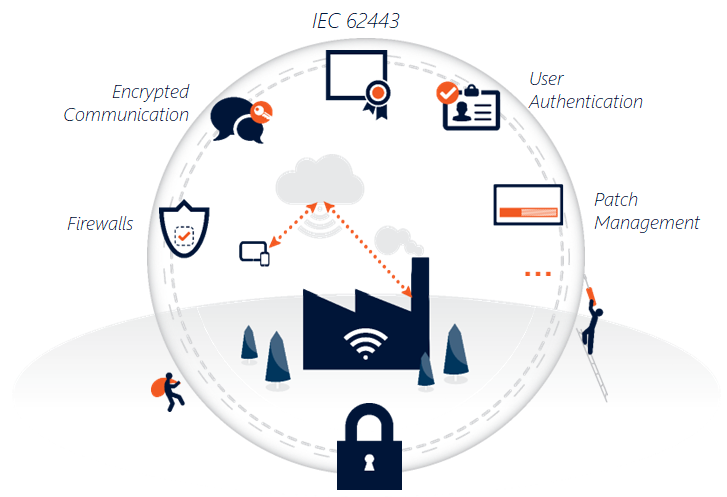

Cyberattacks and other security threats can bring production to a standstill. These threats can also make businesses hesitant to adopt new technologies that can increase their productivity. New technologies, such as IIoT devices, can offer many benefits, but they can also introduce new potential threats. Finding a way to implement new technologies that are well protected against these threats can offer a substantial competitive advantage.

Using certified equipment, but especially software, ensures the necessary cybersecurity. COPA-DATA has received the certificate of compliance with the ISA/IEC 62443-4-1:2018 safety standard from TÜV SÜD, which is part of the German Association for Technical Inspection. This certificate demonstrates that our processes meet the requirements of today’s industrial IT security guidelines. Among the security features built into zenon are encryption, authentication, file signing, secure interfaces, and secure user administration that protect against data loss and other threats. These features make it easy to integrate zenon into your existing security strategy.

Digital software like zenon can play a central role in helping your business achieve greater productivity. The zenon platform provides an integrated solution that connects all levels of your operations, from your sensors to your ERP system. Includes flexible HMI, SCADA, softPLC, messaging, reporting, alarms, and other features, all on a single platform.

You can use zenon to monitor and manage systems and equipment throughout your facility, from your production line to your power system. This gives you greater visibility into your operations and the insights you need to improve the efficiency of your plant.

The zenon platform can be used as a process control system, integrated PLC system, energy management software, automation software and much more. If you’re looking to improve your plant’s productivity, a comprehensive software platform like zenon can be one of the most valuable investments you can make.

Here are some of the companies that use the zenon platform