zenon — The software platform that improves food and beverage production

Leave your details and we will contact you

The food and beverage manufacturing industry is undergoing a transformation in which digital technology plays a significant role. These new technologies offer numerous benefits to food and beverage companies, but they are also changing expectations for the industry and what it takes to succeed.

Having the right technology in place is crucial to making the most of this digital revolution. zenon by COPA-DATA is an ideal solution for food and beverage manufacturers.

zenon helps you reduce your energy consumption, improve product quality, optimize your production lines, integrate systems and increase flexibility in your production processes. You can use it at almost every step of your production process and larger operations, from production to packaging to energy management. It also allows you to implement automation, Industrial Internet of Things (IIoT), and other Industry 4.0 solutions.

The zenon Software Platform is designed to be easy to use and integrate with existing equipment and systems. It combines data recording, equipment operation, and business intelligence in one environment and handles data from all your operations, which helps you get the most out of your information. It’s flexible, scalable, and highly secure to help meet the changing needs of today’s businesses.

Challenges for Food & Beverage Manufacturers

With the globalization of both consumption and production, the food industry is increasingly facing great challenges due to competition, and consequently the need for almost constant launch of new products, increasing regulation and, of course, quality, and public acceptance. These challenges are encompassed in the following topics:

Production process safety

Food and beverage manufacturers are generating more products than ever before, making production and supply chains more complex. Managing production process safety involves consistency between batches and facilities. It ensures product safety and quality, improves your brand image, and creates better visibility into compliance.

Operational efficiency

Manufacturers are under constant pressure to be more efficient to minimize costs and product waste. Efficiency comes from understanding your food manufacturing process, which allows you to identify areas for improvement. When you achieve maximum efficiency, your products will consistently maintain high levels of quality.

Energy Cost Management

Food manufacturing processes require various energy sources, such as steam, carbon dioxide, electricity, water, fuel, and compressed air. By managing your energy consumption, you can identify areas of improvement and make your operations more efficient and profitable.

A comprehensive software platform

Our mission is to make our customers’ lives easier by helping them automate their industrial facilities and manage data more effectively. Therefore, the zenon Software Platform enables efficient processes in food and beverage production, from small breweries to global players. zenon ensures efficiency, transparency and supports continuous improvement processes to help you do better by making products better than possible.

Features of the zenon Software Platform for automating food and beverage production processes

The zenon process automation software platform, due to its large presence in the segment, has been incorporating the know-how of food and beverage manufacturing processes over time and can help you continuously improve all areas of your plant and control your operations. As a result, you can increase plant profitability, compliance with worldwide standards, and your customer satisfaction. This platform supports the entire production team, from machine operators to management.

These specific features of the zenon platform will help you, as a food or beverage manufacturer, achieve your production goals:

- Machine operation and control: This level of control over machines allows your operators to use them more safely and efficiently, while also getting relevant information at the right times.

- Data acquisition: The zenon Software Platform can connect to various types of devices without any data loss, performing tracking in accordance with the ISO 22000 industry standard.

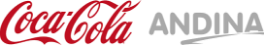

- Plant supervision: Oversee the processing, packaging, utilities, water treatment, and building automation areas of your plant. As a result, you’ll gain complete control over your operations, improve the quality of your process, and have the information you need to react quickly to emerging situations.

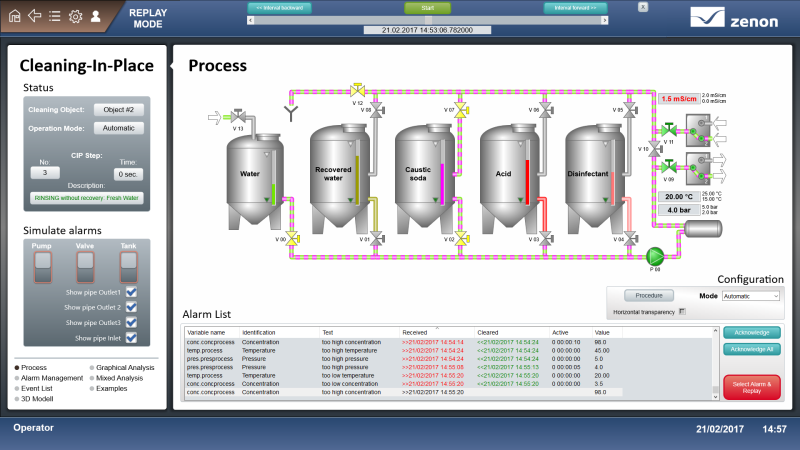

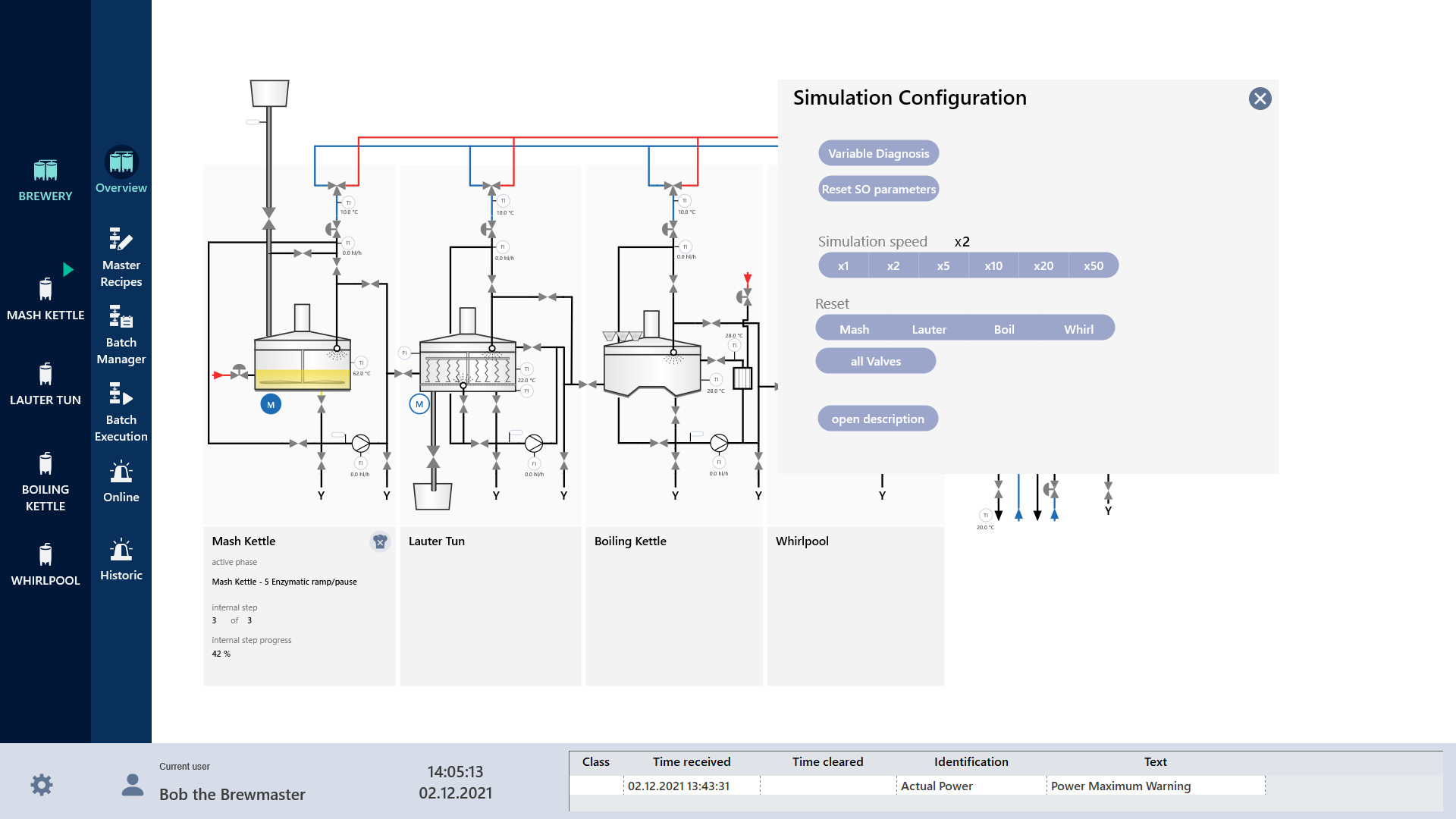

- Batch Control: Control each batch to ensure consistent quality, error-free operation, and flexible and efficient production. Our batch controls and recipe management are intuitive, easy to implement and operate, making it possible to correct deviations during the production of a batch, avoiding unnecessary waste.

- Production reporting: The zenon Software Platform has ISO 50001-compliant reporting tools to identify areas for improvement to reduce downtime and optimize consumption.

- Deployment of operating instructions: With the zenon Software Platform, beverage manufacturers can use interoperability for plant integration and performance. Send data and instructions from the HMI to the ERP and vice versa.

How zenon helps food and beverage manufacturers

The zenon software platform is flexible and scalable and has tools and functionalities that improve operations in the food and beverage industry in the following areas:

Plant Information Management: Get an overview of your plant to standardize data, increase efficiency, and improve production.

Effective line management: The zenon platform integrates machines, equipment and devices, whether from any manufacturer, including legacy ones, into your production line, so you can control processes in real time.

Process automation: zenon helps you with a wide range of powerful features to enable flexibility, consistency, and efficiency in your batch processes.

Better quality management: You can use the zenon Software Platform to control production and ensure product quality in each batch to avoid failures.

Improved utility system monitoring: zenon software provides increased availability and quality of your utility resources through efficient displays and controls.

Energy data management: Connect energy data sources to zenon and the platform will analyze the information to identify savings opportunities.

Building automation: Connect your building systems to the zenon Software Platform for operational oversight, safety, and availability.

Some of our clients