Energy data management for greater production efficiency

Leave your details and we will contact you

What is an Energy Data Management System (EDMS)?

Energy data management systems (Energy Data Management System), or EDMS, use devices and sensors, including the Internet of Things (IoT) to collect real-time consumption data. Instead of collecting this data manually, an EDMS does this work for you, automatically, and provides reliable data for reporting purposes. An EDMS is part of a higher-level EMS energy management system.

Users at manufacturing companies or industrial equipment manufacturers can actively monitor energy consumption and take real-time action to reduce it.

Ultimately, it’s about reducing consumption, increasing efficiency, as well as reducing carbon-emitting processes. By using an energy data management system, you can bring more transparency to your energy consumption mix and identify your company’s biggest consumers.

A functioning energy data management system is the foundation of a fully automated factory, a smart factory or a connected factory.

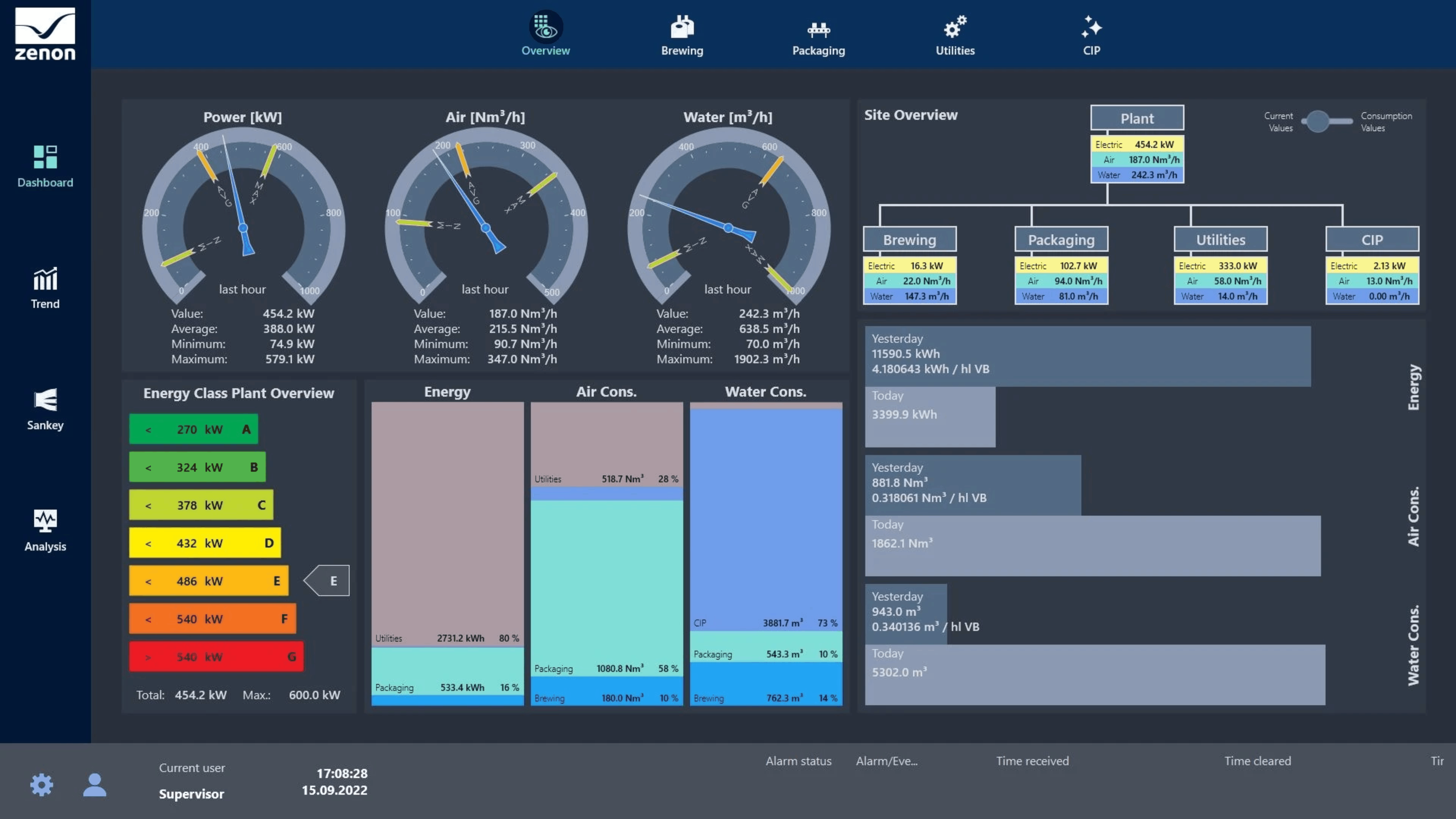

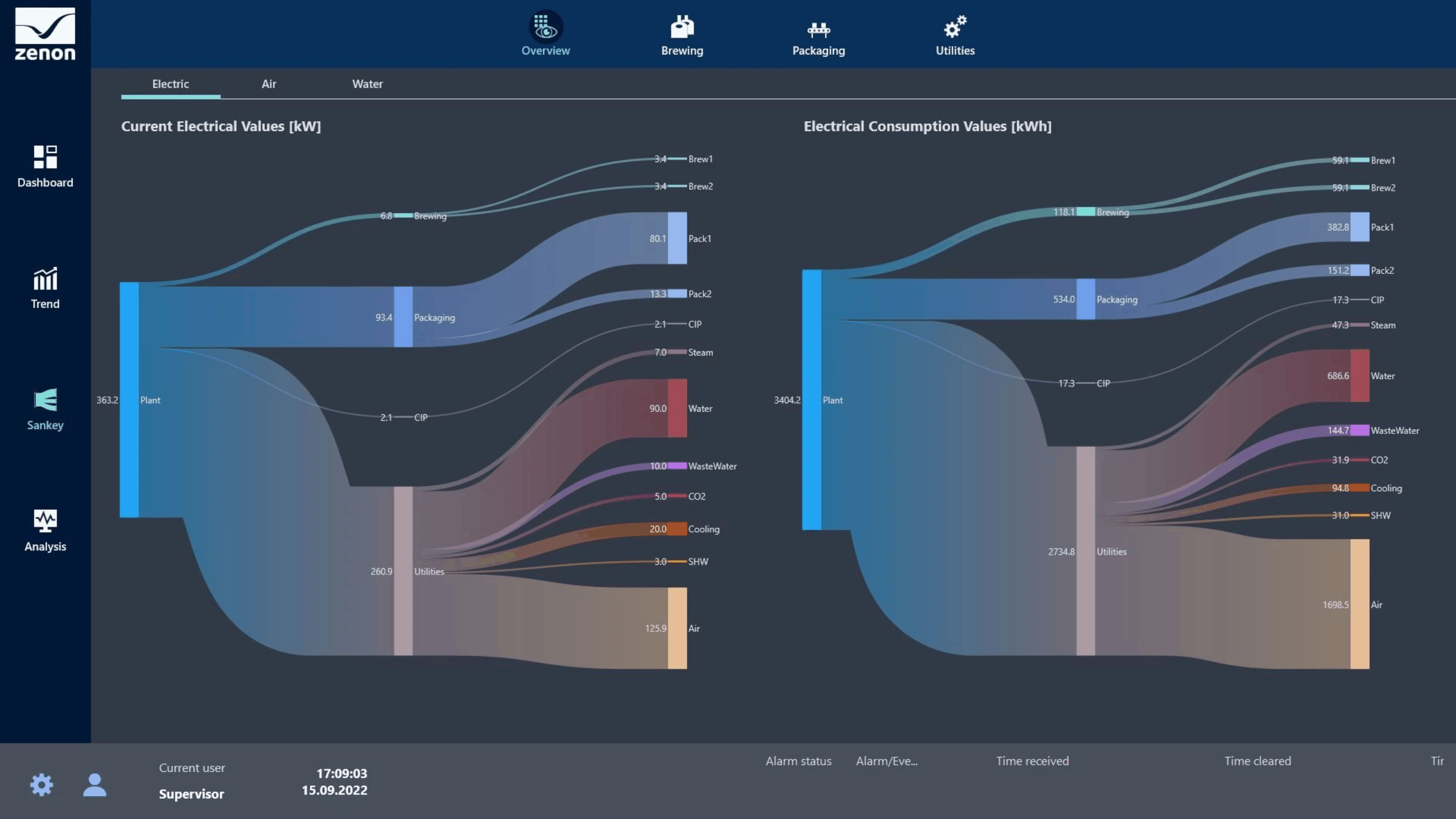

It collects data from your production processes and provides a real-time picture of energy consumption, from your unitary equipment, to the entire plant. This allows you to reduce potential environmental pollution caused by high consumption and, at the same time, reduce costs.

Sustainable energy data management to optimize your industrial processes

Rising energy costs and limited resource availability are encouraging society and industry to change their views and behaviors.

An EDMS with the zenon platform generates synergies between cost optimization and environmentally future-oriented production models. That way, you can take proactive steps.

Get a real-time overview of the energy consumption of your production processes, identify the biggest consumers and automatically level load peaks.

In addition to continually recording and documenting your energy flows, you can reduce operating costs and take action on the increasingly important path to sustainability.

A software platform as a partner

The zenon software platform helps you address the many challenges of energy data management.

Environment and sustainability

Environmental responsibility: Comply with your sustainability principles and corporate social responsibility. Actively participate in addressing ESG sustainability challenges and make an impact today for the future.

Budget: The objective is to generate maximum output with the limited resources available. It is important to gradually optimize energy consumption.

Data: Managers need energy data to make informed decisions about productivity and performance. However, manual reports based on data sampling do not provide sufficient real-time information for such analyses. As a result, valuable productivity improvement opportunities can be easily overlooked without the detailed insight provided by a comprehensive energy data management system.

Standards for Government Financing: To be eligible for government subsidies, a company may have to meet certain efficiency standards. The associated regulations are often very extensive and difficult to implement without the support of a prepared platform.

Optimization of engineering processes and equipment

Define your most important internal performance indicators (KPIs) and track energy flows and manufacturing processes.

Data analysis and monitoring can provide a foundation for your business success.

Optimize your workflows and processes continuously and constantly.

Identify your energy baseline while also identifying your energy performance indicators (EnPIs) in addition to your KPIs.

Quickly identify your company’s biggest energy consumers to understand where to focus efforts. The information helps you continually reduce your energy costs.

Analyze your load profiles and record power spikes, so you can avoid startup spikes and reduce them in the long term.

Collect data from multiple sources. In most industrial plants, you will find multiple systems and equipment in use, each with different energy consumption profiles. It is therefore important that data collection also includes energy consumption in individual production lines/areas and building facilities. An integrated energy data management system provides an overview of all consumption.

Get an overview of energy consumption. An EDMS collects data from multiple sources, providing a snapshot of your energy consumption. This information is stored centrally, making it easier to identify possible trends and adjust your processes when necessary.

Monitor new and existing asset data. Older systems often don’t offer the same efficiency as newer models. With an energy data management system, you can compare the energy consumption of new and existing machines to increase efficiency and ensure effective consumption monitoring.

Determine areas for greater energy efficiency. With an EDMS, you can access trend reports and data on your equipment’s performance, which can help you identify less efficient areas. You can then flag high-power, low-performance equipment to focus maintenance or replacement efforts.

How zenon supports its energy efficiency and ISO 50001 certification

A powerful platform like zenon helps you manage energy consumption across all industrial processes, improve the energy efficiency of your operation and meet the requirements for ISO 50001 certification. With zenon you:

Collects and processes all data automatically. zenon is a next-generation software platform with over 300 communication protocols. This allows you to integrate all PLCs and computer systems and process targeted queries from any data server. Advanced communication and diagnostic functions ensure you always receive accurate information for your analyses.

Archive and manage data for ISO 50001 certification. Use real-time functions to track and record current operational data or zenon Historian 360 to evaluate historical data. If you need data for your ISO certification, you can easily access it with zenon and display it clearly in various formats.

It benefits from a simple system implementation. Thanks to its high adaptability, you can easily integrate zenon into your existing scenario. Intuitive modules and a user-friendly design help you quickly perform calculations, activate machines, onboard devices, and add new users. Combined with extensive training and maintenance plans, the zenon platform is a valuable investment for any team.

Displays data clearly and in an easy-to-use way. Industrial processes are always associated with extensive data collection. For example, it provides trend curves, power analyses, performance indicators, alarm messages, and event lists.

Choose the zenon platform as your energy data management system

With zenon, you streamline your energy data collection and gain access to valuable reporting and trend analysis. COPA-DATA has more than 30 years of experience in the industry and continually improves the zenon platform to not only meet demands, but, most importantly, anticipate them, in order to offer the best energy management solution to our customers.