MODULAR TYPE PRODUCTION

Modular Production with zenon: explore the full potential

Leave your details and we will contact you

Diversification of production with few devices – the great potential of modular production

The growing demand for individual and small-batch solutions is leading to shorter product cycles and innovations. This is a challenge facing the pharmaceutical industry and the process industry, in particular. Conventionally structured production plants in the fields of chemistry, food, cosmetics, and pharmaceuticals are often not flexible and agile enough. They are unable to effectively manage the introduction of new products or changes in their production variants. Digitalization and modularization offer solutions to these challenges as they simplify the process. Modular production allows the overall task to be subdivided into small parts. In contrast to previous monolithic approaches, the production process is divided into individual, standardized services. Logical interconnection allows individual modules to be connected in several different ways, also known as plug&produce. The result is a high-performance solution for agile manufacturing that not only offers advantages for the pharmaceutical industry and process manufacturing, but also for many other segments.

Cross-industry advantages of modular manufacturing

High innovative capacity

Modularization reduces the investment risk associated with the entry of new products, as production capacity can be adapted to the market, thus ensuring greater competitiveness.

Reduced production costs by 40%*

Efficient configuration of modular plants reduces the conversion/start-up costs of a production plant. Reduced production costs are especially noticeable when producing small batches.

50%* faster time-to-market

Time-to-market is significantly shorter in modular production, as most engineering takes place using prefabricated modules. These can be integrated into the process control system with minimal cost. Scaling from the lab to the production phase is also much easier, thus reducing overall product development time.

Maximum flexibility

The flexibility of plant use increases considerably thanks to modularization, as modular units can be reused or easily replaced without any additional engineering expenditure. The freedom that zenon offers of not being tied to machines from specific manufacturers further increases flexibility.

Module Type Package – a paradigm shift in production

The basic requirement for consistent modularization in production is a uniform description of the information about the individual modules. Which data objects are logged? What services should be performed? The description is uniformly supplemented by the independent standard “MTP” (Module Type Package) between industries and manufacturers. All information is provided in a standardized format, making it easy to integrate into a higher process orchestration layer (zenon POL). zenon POL and zenon Engineering Studio interlock in a fully automated way. All work steps are therefore automated and transferred to the Service Engine (runtime) via the POL, resulting in a fully automatically generated process control system (DCS) in just a few steps.

Most of engineering already incorporates modular engineering concept. Subsequently, the integration of fully automated modules into the process control system involves much less cost for engineering. Older existing plants can be MTP-compatible and integrated into POL without excessive programming costs using the built-in zenon SoftLogic.

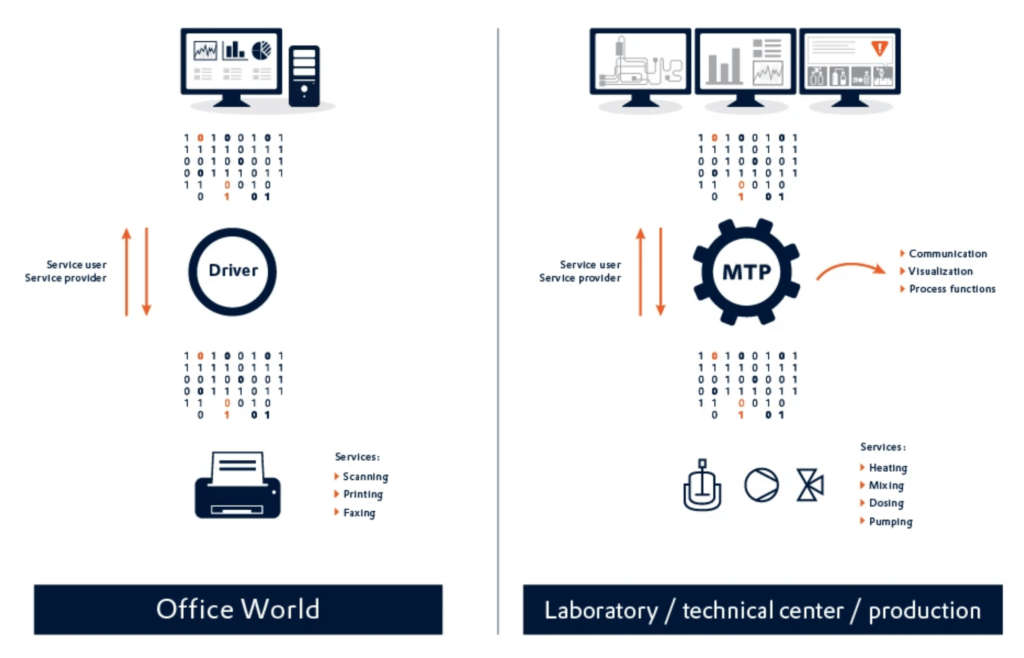

As an idea, MTP can be compared to a printer driver. The printer (a subsystem) is connected to a central computer that is independent of the manufacturer. The goal is to make connecting the device as simple as possible to allow it to be used when required. The computer can easily access the “print” or “scan” services. Similarly, the POL detects the available services of the individual modules via MTPS and can access them directly. “Plug and print” becomes “plug and produce” in factory automation and process engineering – after all, digitalization can be easy, even on a larger scale!

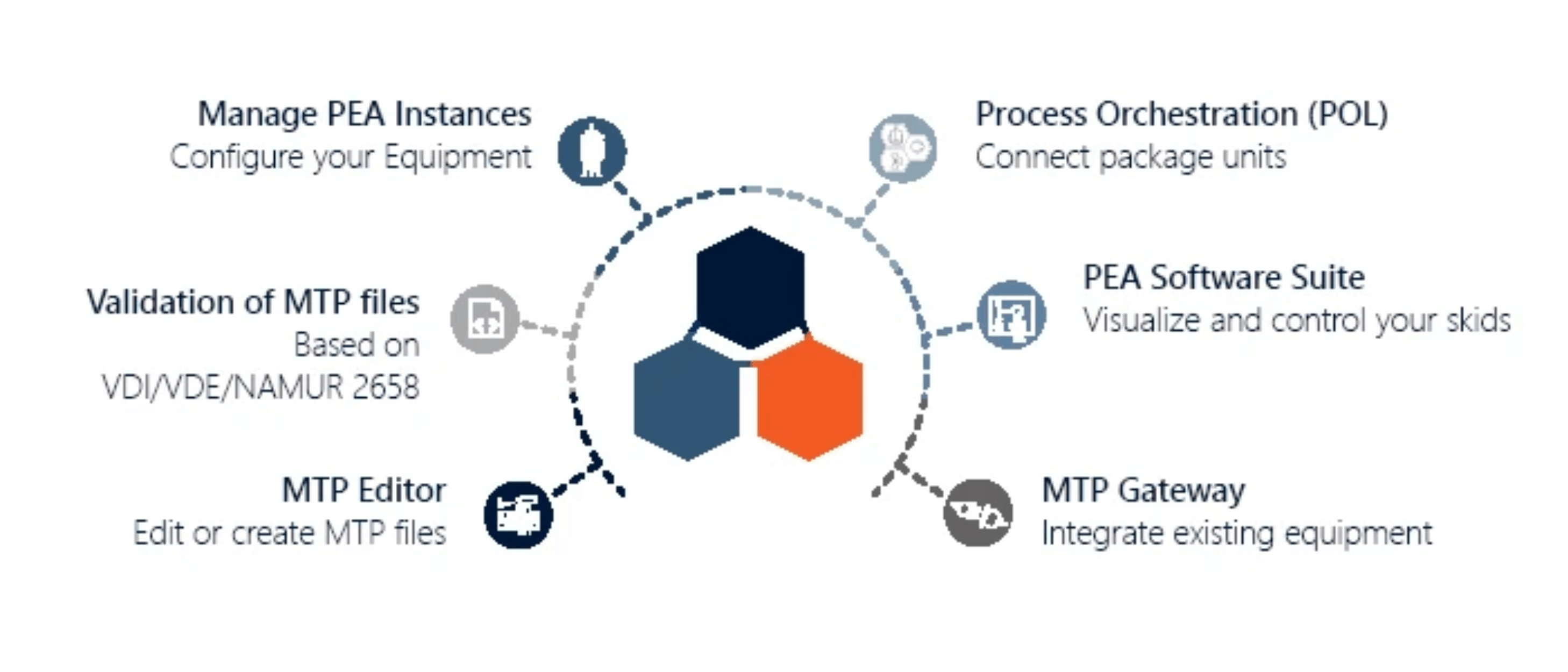

zenon MTP Suite from COPA-DATA provides all the services you need to implement end-to-end modular production. Optimize your company’s existing production processes and benefit from agile manufacturing that meets all relevant standards.

- The MTP Editor makes it easy to create and edit MTP files for both new and legacy systems. Each step is checked in real-time to ensure that the process complies with the VDI/VDE/NAMUR 2658 standard.

- The COPA-DATA Validation Service for MTP files checks if new MTP files are compatible – even during configuration. Once imported into zenon MTP Suite, all files are managed in a central database. This provides operators with an overview at any time of all MTP files in use.

- Each MTP file is a template for a specific piece of equipment. If you have multiple pieces of equipment of the same type, multiple instances can be created from the template using the service to manage Process Equipment Assembly (PEA) instances.

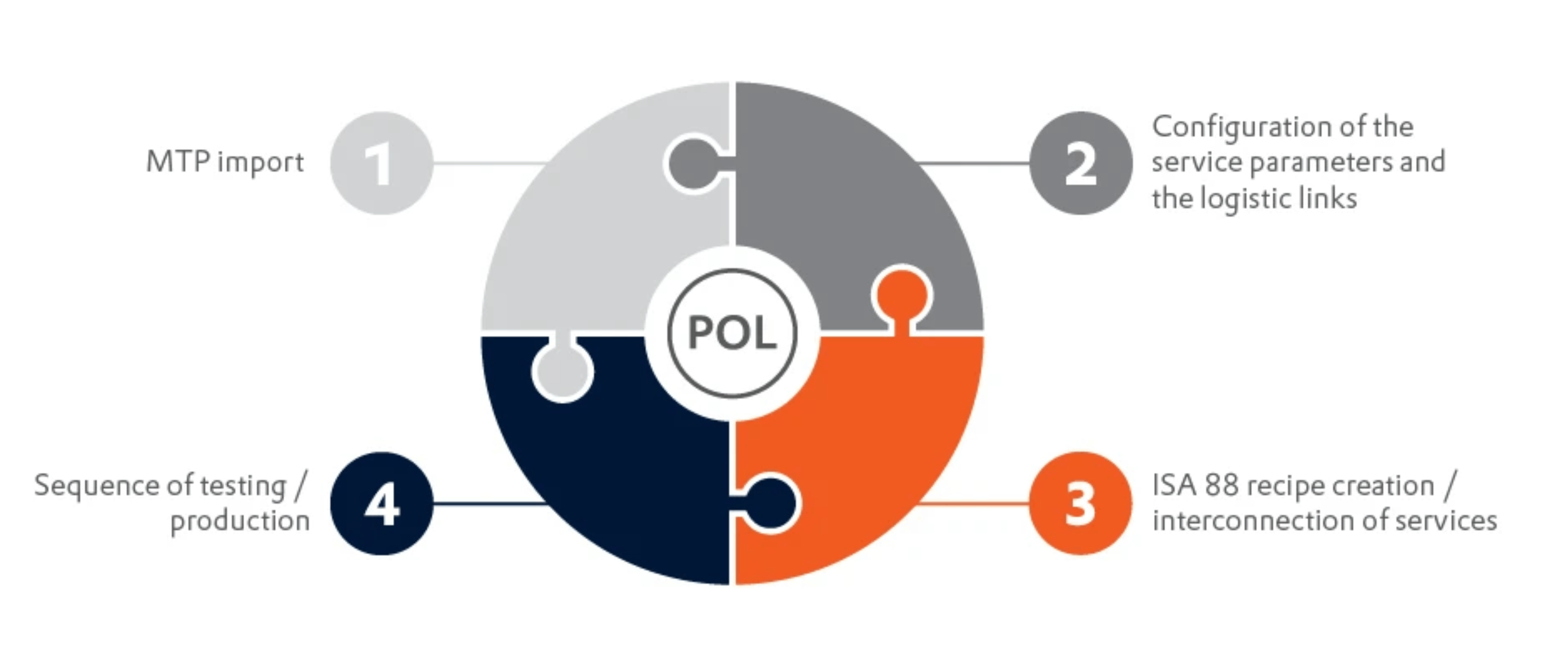

- In the Process Orchestration (POL) step, users link the newly generated PEA instances and logically connect the equipment via drag-and-drop into a graphical editor. All process images, variables, basic functions for ISA 88 batch control, OPC UA configuration, reports, alarms, and audit trails are automatically generated at the push of a button.

- With the PEA Software Suite, COPA-DATA provides operators with a local control system directly on the machine. A state-of-the-art, easy-to-use HMI – including features such as ISA-88 batch control, user management, and audit trails – allows operators to manage processes safely and ergonomically. The app also ensures data integrity in accordance with FDA 21 CFR Part 11 and Annex 11 of the EU GMP guidelines.

If legacy equipment needs to be MTP-compliant when setting up modular production, MTP Gateway can help. It connects legacy systems and sends the relevant information for orchestration via OPC UA and according to MTP standards. This ensures that users remain independent of the manufacturer and can choose the machines and software solutions that best suit their needs.

Modularization – Service-oriented and independent of equipment manufacturer

MTP – modular production with zenon by COPA-DATA

COPA-DATA has been committed to simplifying processes with digital and automation solutions for more than 30 years. Today, the technology behind it has a name: MTP. We draw on our extensive experience to continuously advance the zenon software platform.

You can rely on us to meet your modular production requirements, now and in the future. When well thought out, modularization via MTP can revolutionize the process manufacturing industry and make it competitive for the future.