zenon in the manufacture of machinery and equipment

Add value to your products with world-standard machine builder software

Leave your details and we will contact you

Machinery and equipment are an ever-evolving market that constantly sees the emergence of new technologies, security challenges, data demands, and more. To remain competitive in the era of Industry 4.0, manufacturers need future-proof operating software for their machines that meets their changing needs and, ideally, also increases productivity while enhancing the products they offer to their customers.

zenon software is an innovative and secure platform for the machine building industry. From automated engineering to integrated reporting, discover how equipment manufacturers (OEMs) are increasingly using zenon to transform their customers’ manufacturing operations to help them grow their businesses.

The zenon platform has a range of features that ensure the efficient operation of machines and equipment within a plant context, but also of stand-alone machines.

The platform is present and producing efficiently in various industry sectors, including pharmaceutical, food and beverage, automotive, and others. When used for machine building, zenon offers unrivalled benefits in engineering, commissioning and during operation.

Applications and Benefits for Machine Building

Engineering

Automatic engineering

zenon handles the configuration of equipment and systems in a fully automated manner. zenon Engineering Studio allows you to automate repetitive tasks such as importing variables and creating graphics, even with several ready-made and tested commonly used elements available, significantly reducing the potential for errors. Or create your own smart, flexible objects and use them in your future projects. Thanks to zenon, complexity is now fully under control.

Modularization

Conventional production equipment is neither flexible nor efficient enough to meet the growing demand for customer-specific individualization, driven by the introduction of new products and an increase in their variants. This is where zenon comes in. With a modular approach to construction, machine builders can develop process equipment with more options for custom production.

Starting with version 8.20, zenon Engineering Studio has introduced Smart Objects, which can be used to make design engineering even simpler. These Smart Objects are composed of standardized functional units that go into all the module configurations and functions required to map a process component. Once you’ve created your Smart Object models, they can be grouped multiple times in your projects, with the links and objects being automatically generated by the software.

Decentralized intelligence for modular applications reduces engineering work through autonomous equipment modules and helps users react quickly to fluctuating market demands to stay competitive. Another key benefit of modularization comes down to the ability for a module to be used repeatedly, without having to be rewritten. Reusing existing modules doesn’t require high-cost new developments, potentially saving your company time and money.

Versioning

Connectivity

zenon software helps facilitate this connectivity as it has its own drivers and protocols, as well as supporting more than 300 communication protocols and open interfaces, which allows it to connect seamlessly with most machines and systems. This allows the machines to communicate with each other as well as with other systems, ERPs, for example. While the customer’s machines communicate with each other, zenon’s OPC UA Server ensures that your data remains secure. zenon’s OPC UA Server is backed by a certification from the OPC Foundation.

In addition, zenon can serve as a basis for networked factories, as zenon-equipped machines can integrate seamlessly and securely into IIoT infrastructures. OEMs can offer this feature to their customers as a way for their equipment to outperform the competition.

Safety

zenon’s security features include 128-bit communication encryption, easily configured user authentication, and file signing, which allows zenon to recognize manipulated program files. Role-based user administration allows you to set the level of access in zenon Engineering Studio and Service Engine for any user in Active Directory. Changes to the Service Engine can be synchronized to Engineering Studio remotely in real time. There are 128 different access levels available. You can add as many users as you want.

zenon also offers continuous redundancy, which ensures that no data is lost if a computer fails. Even in the time between the breach and when the backup server takes over, perfect redundancy ensures zero data loss. Not having to worry about data loss is a huge plus for your engineering efforts, helping your team recover lost data quickly and stay on schedule. zenon redundancy is also easy to set up. All you must do is set the server and the server to standby.

Individual adaptation

The zenon Engineering Studio user interface is available in different languages, and you can use as many languages as you need in Service Engine, even at the configuration stage. This capability makes the system easier to use and allows for cooperation between facilities in multiple countries.

In addition to switching between languages, zenon can be adapted in many other ways to the needs of machine builders. For example, many users like how individual adaptation allows them to switch color palettes when they need to improve visualization or, for example, correlate the palette with the shift or with the product being produced, or even with the time. Other popular components of zenon’s individual tailoring features include the user’s ability to set up dashboards, create their own set of trends, and switch the way they navigate. Individual visual adaptation can contribute to the inclusion of individuals with certain degrees of visual impairment in this labor market. Individuals with color blindness, for example, can naturally operate a machine or process if, during their shift, the human-machine interface, instead of presenting the palette with colors, presents itself with shades of gray.

Commissioning

During the commissioning process, machine builders need to ensure that their products are properly designed, installed, and tested safely, operated correctly, and maintained responsibly. With zenon, you examine all the various components of the equipment and verify that each part is working properly. If a problem occurs within the system, with zenon it is very easy to identify its source. This way, problems can be isolated and corrected before they become costly and reduce the efficiency of your operations.

Network

Horizontal and vertical integration is crucial for creating a smart factory and enabling communication between machines and systems across the network. With zenon software, integration is very easy and fast, thanks to its more than 300 communication drivers available, even in environments with equipment from different manufacturers.

With zenon’s Hot Reload feature, technicians update designs at any time and activate changes without downtime. This allows them to adapt to new information and keep the system up to date without losing valuable time due to equipment shutdown.

Integrations with third-party systems

In production

Learn more about the numerous features your customer can employ using zenon in their day-to-day operations:

Customizable human-machine interfaces

HMIs serve as the interface between operators and the machines they work with, making them crucial for the user-friendly operation of the machine. As customization becomes more common in the industrial sector, customers increasingly want HMIs tailored to their equipment. If a customer approaches a machine builder like you with a specific vision in mind, zenon makes it easy for you to bring that vision to life.

In addition to customized HMIs for each customer, zenon also allows you to offer user-defined HMIs through their adaptability according to individual needs and preferences. With zenon, users can easily change display colors, languages, and measurement units, and rearrange widgets to customize the dashboard. You can also create different dashboards, with different permissions and settings, for different user levels.

Smart Checklist

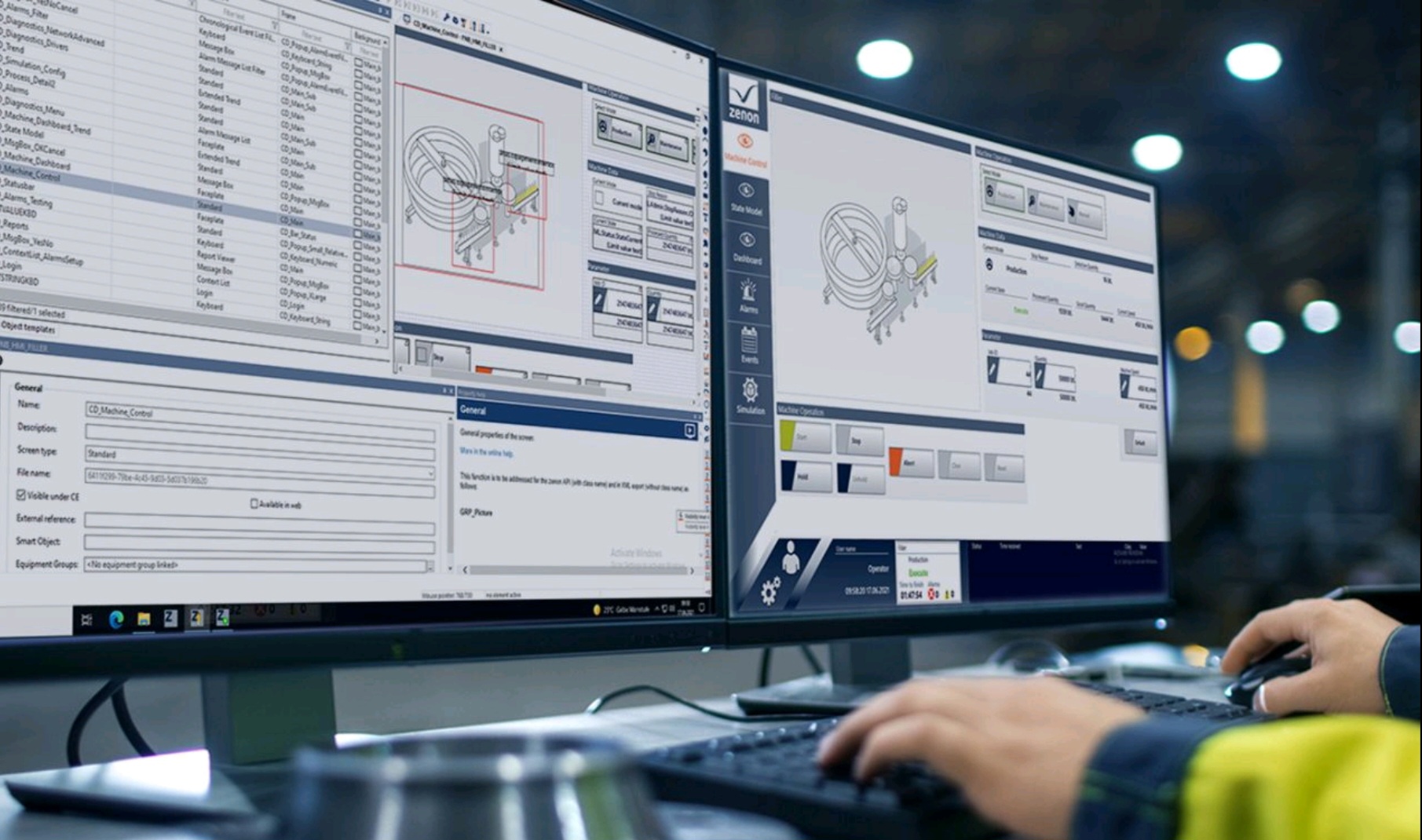

Recipes

With zenon, users define how they manage recipes without extra programming or additional software. The program offers models that allow for rapid engineering as well as extensive flexibility. They can easily set the status of a recipe according to their needs and set their own status handling rules. In addition, they easily import recipes from other systems and export them as needed. The handling of the recipe at zenon also complies with international safety specifications.

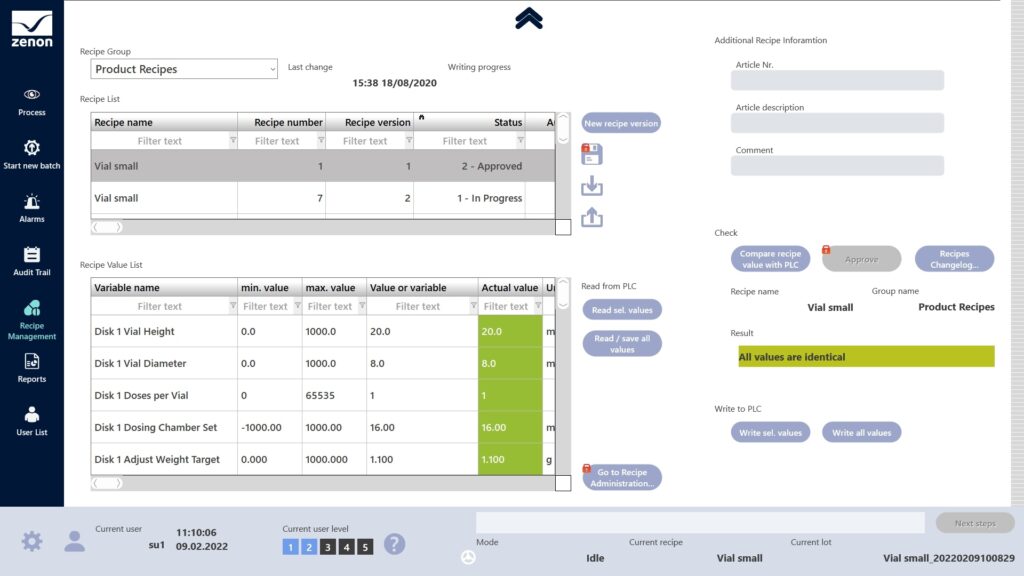

Reporting

zenon makes it easy to display important information related to production batches, energy consumption and more directly on a machine’s operator panel. Fully integrated with zenon, operators benefit from custom reports with minimal engineering and no additional software tools. Reports are also displayed in a user-friendly and easy-to-read format, helping operators improve machine performance.

Product Life Cycle

At COPA-DATA, we are constantly updating our software platform to ensure that it keeps up with the changing demands of our key industries. We offer regular updates and take steps to give users as much flexibility as possible and ensure that updates go smoothly. In this way, we also ensure that all new versions of zenon are backwards compatible. This means that machines running the latest version of the software can still communicate with those running an older version.

Users easily convert projects to the latest version of zenon without risk of loss. You can also create projects in Engineering Studio in the current version that are backwards compatible. This means that even when you upgrade machines or software, projects can continue to run without interruption.

Some of our clients